15-5 PH Plate

Home » 15-5 PH Plate

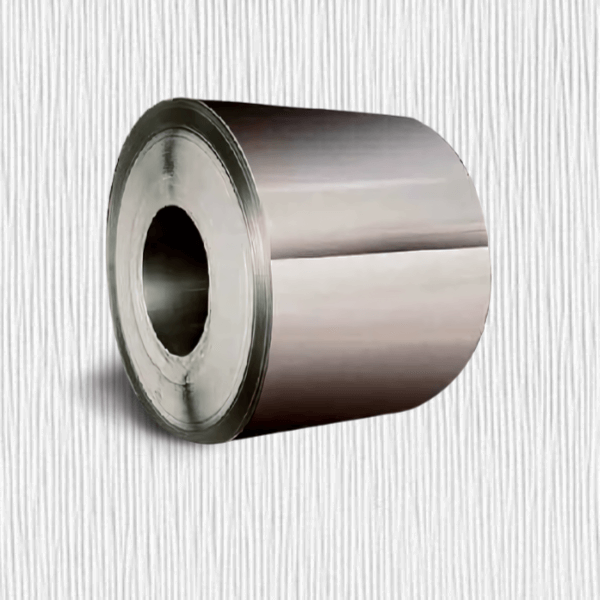

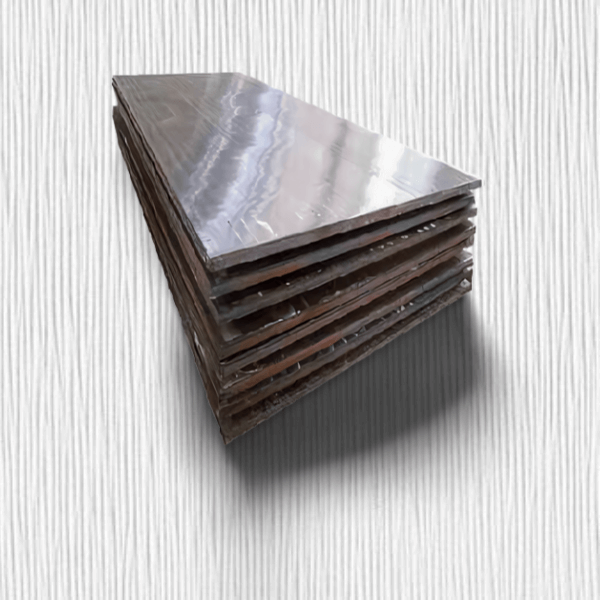

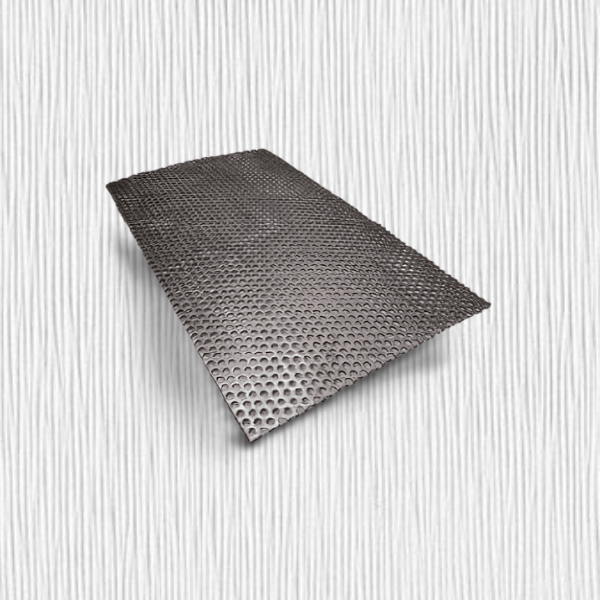

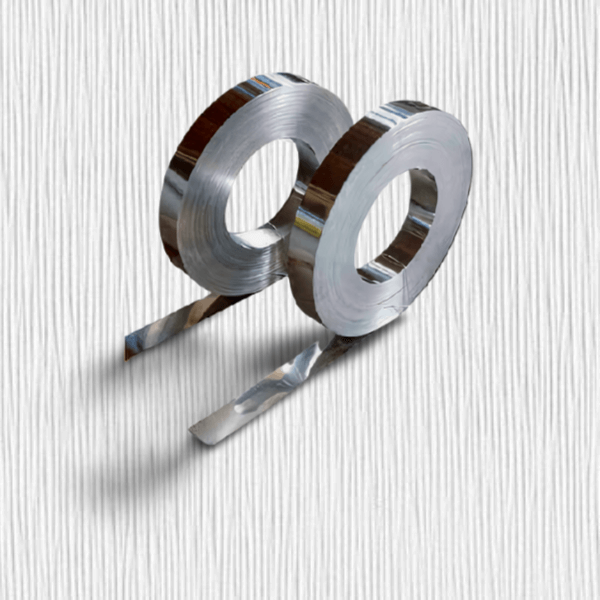

UNS S15500 Ring, DIN 1.4545 Hot Rolled Sheet, ASTM A240 15-5PH CR Sheet, DIN 1.4545 Shims, UNS S15500 Foil Sheet, ASME SA240 15-5PH Rolls, ASTM A240 15-5PH Sheets, ASME SA240 15-5PH Coil, UNS S15500 Plain Sheet, UNS S15500 Circle, ASME SA240 15-5PH Flats.

15-5 PH stainless steel is a high-strength, corrosion-resistant alloy steel containing chromium, nickel, copper and niobium. The “15” refers to the approximate chromium and nickel composition of 15% and 5%, respectively. The “PH” designation means it can be precipitation-hardened to achieve very high strengths.

This steel displays excellent mechanical properties combined with resistance to rusting and corrosion. In addition, it retains high strength even when exposed to high temperatures up to 600°F. This versatility makes 15-5 PH steel suitable for use in systems like turbines, boilers and chemical processing equipment.

The niobium and copper in ASTM A240 15-5PH Coil stainless steel contribute to achieving very high yield and tensile strengths while maintaining reasonable ductility and toughness. Properly treated and tempered plate stock can display yield strengths above 150,000 psi. The high-temperature properties exceed those of regular 300-series stainless steel.

UNS S15500 plates can be easily welded and machined. This adds to its fabrication flexibility for building large-pressure equipment or very small precision components. Parts made of this steel resist corrosion in various environments, including fresh water, brine solutions and several organic chemicals. It serves well in oxidizing, neutral and moderately reducing environments.

The 15-5 PH plate offers an excellent combination of hardness, corrosion resistance and high-temperature strength. For example, a plate can reach a hardness of 44 HRC while still retaining proper corrosion resistance suitable for cutlery. By changing heat treatment schedules, hardness values between 30 to 48 HRC are possible.

Being a single-phase alloy after hardening and tempering treatments, a DIN 1.4545 Polished Plate achieves very impressive fatigue strength. This is very useful in dynamic stress-loading applications such as aircraft landing gear components. The copper in this steel resists corrosion in sulfuric acid, making it suitable for chemical plant scrubbers and slurry pumps.

The 15-5 PH stainless steel plate offers good ductility and toughness, which is suitable for the aerospace sector to make engine and airframe forgings. The fine-grained microstructure protects against crack initiation and propagation – which is necessary for fail-safe performance.

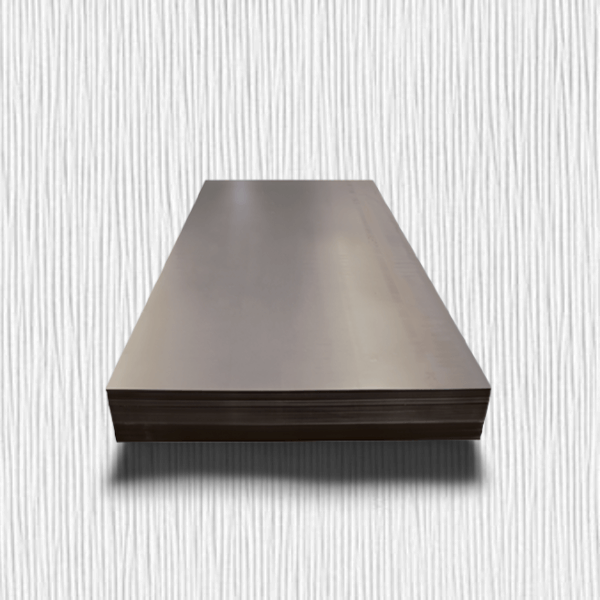

Specification Of 15-5 PH Plate

| Specification | ASTM A240 / ASME SA240 |

| Dimensional specification | ASTM, ASME and API |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 1.0mm – 200mm |

| Range | 5 mm To 50 mm thick in 1000 mm TO 1250 mm width & 2500 mm Length. |

| Production | Hot-Rolled (HR) / Cold-Rolled (CR) |

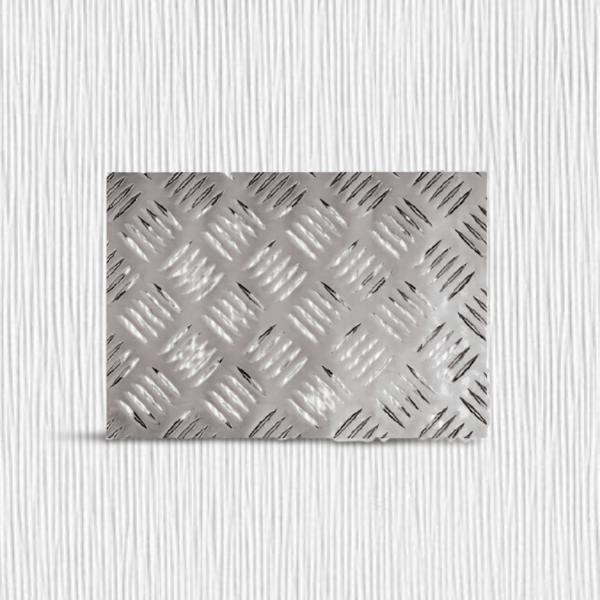

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

Price List Of 15-5 PH Plate

-

ASTM A240 15-5PH 2B Finish US $3 – $8 / Kg

-

ASME SA240 15-5PH Coil US $4 – $9 / Kg

-

UNS S15500 Circle US $2 – $10 / Kg

-

DIN 1.4545 Clad Plate US $5 – $10 / Kg

-

ASTM A240 15-5PH CR Sheet US $3 – $10 / Kg

Equivalent Grades Of 15-5 PH Plate

| STANDARD | WERKSTOFF NR. | UNS |

| SS 15-5 PH | 1.4545 | S15500 |

Chemical Composition Of 15-5 PH Plate

| Grade | C | Ni | Si | Mo | Mn | P + S Max | Cr | Cu | |

| SS 15-5PH | min. | – | 3.50 | – | – | – | 0.03P | 14.00 | 2.50 |

| max. | 0.07 | 4.50 | 1.00 | 0.50 | 1.0 | 0.015S | 15.50 | 4.50 | |

Different Types Of 15-5 PH Plate

Our Manufacturing Process Of 15-5 PH Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Stainless Steel Plate

Our Material

Contact Us

Supplying World Wide