17-4 PH Flanges

Home » 17-4 PH Flanges

UNS S17400 Screwed Flange, DIN 1.4542 RTJ Flange, ASTM A182 SS 17-4 PH Forged Flange, UNS S17400 Sorf Flange, DIN 1.4542 Loose Flange, ASME SA182 SS 17-4 PH Reducing Flange, DIN 1.4542 Weldo-Nipo Flange, ASME SA182 SS 17-4 PH Lap-Joint Flange, ASTM A182 SS 17-4 PH Square Flange.

Renine Metalloys, a pre-eminent manufacturer and supplier, takes pride in offering SS 17-4 PH Flanges to a global clientele. Forming part of the high-end austenitic stainless steel grade, these flanges can be accessed in various categories, specifics, and dimensions. We adhere strictly to the outlined quality standards and manufacturing processes in producing these flanges, which find extensive applications in industries like chemical equipment and heat exchangers. The ASTM A182 SS 17-4 PH Square Flange demonstrate exceptional oxidation resistance up to 1600 °F. They are engineered to offer specific alloy characteristics enhanced with superior intergranular corrosion resistance. They are immune to weld decay when exposed to mildly corrosive environments.

The UNS S17400 Screwed Flange consist of titanium-stabilized chromium and nickel austenitic stainless steel, valuing remarkable strength and excellent corrosion resistance. They are supplied in the annealed condition. Spanning high, low, and medium variants, these flanges offer matchless strength and durability. Our flanges feature multi-faceted characteristics such as durable performance, precise dimensions, excellent corrosion resistance, and minimal maintenance requirements. We also offer these flanges in customised sizes and specifications to cater to our valuable clients’ peculiar needs at competitive prices.

At Renine Metalloys, our adept and qualified professionals engineer the flanges in alignment with international and national quality standards. Our manufacturing team harnesses the latest techniques and advanced tools, ensuring the fabrication of dimensionally accurate and durable flanges. This process unfolds under the watchful guidance of our experienced experts. Throughout the manufacturing process, our experts provide the equipment used for fabrication is subjected to regular checks and updates, mitigating potential errors during the production stage. The DIN 1.4542 Loose Flange flaunt outstanding flexibility, durability, and weldability properties, rendering them suitable for many applications.

Specification Of 17-4 PH Flanges

| Specifications | ASTM A182 / ASME SA182 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of 17-4 PH Flanges

-

ASME SA182 SS 17-4 PH Spectacle-Blind Flange US $3 – $8 / Kg

-

ASTM A182 SS 17-4 PH Square Flange US $4 – $9 / Kg

-

DIN 1.4542 Swrf Flange US $2 – $10 / Kg

-

UNS S17400 Threaded Flange US $5 – $10 / Kg

-

ASME SA182 SS 17-4 PH Weld-Neck Flange US $3 – $10 / Kg

Equivalent Grades Of 17-4 PH Flanges

| STANDARD | WERKSTOFF NR. | UNS | AFNOR | JIS | GOST | EN |

| 17-4PH | 1.4542 | S17400 | Z6CNU17-04 | SUS 630 | – | X5CrNiCuNb16.4 |

Chemical Composition Of 17-4 PH Flanges

| TYPE | Cr | Ni | Cu | Cb + Ta | C | Mn | P | S | Si |

| 17-4 (H900) | min: 15.0 max: 17.5 | min: 3.0 max: 5.0 | min: 3.0 max: 5.0 | min: 0.15 max: 0.45 | 0.07 max | 1.00 max | 0.04 max | 0.03 max | 1.00 max |

Mechanical Properties Of 17-4 PH Flanges

| Grade | Tensile Strength ksi (MPa) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Rockwell) MAX |

| SS 17-4 PH | 170000 psi | 140000 psi | 6% | 38 |

Different Types Of 17-4 PH Flanges

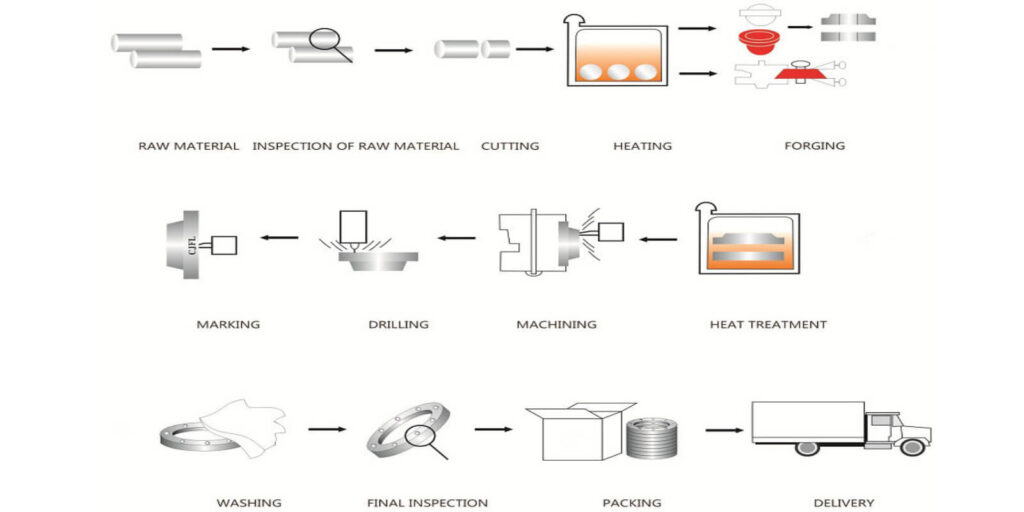

Our Manufacturing Process Of 17-4 PH Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Stainless Steel Flanges

Our Material

Contact Us

Supplying World Wide