Hastelloy C276 Fasteners

Home » Hastelloy C276 Fasteners

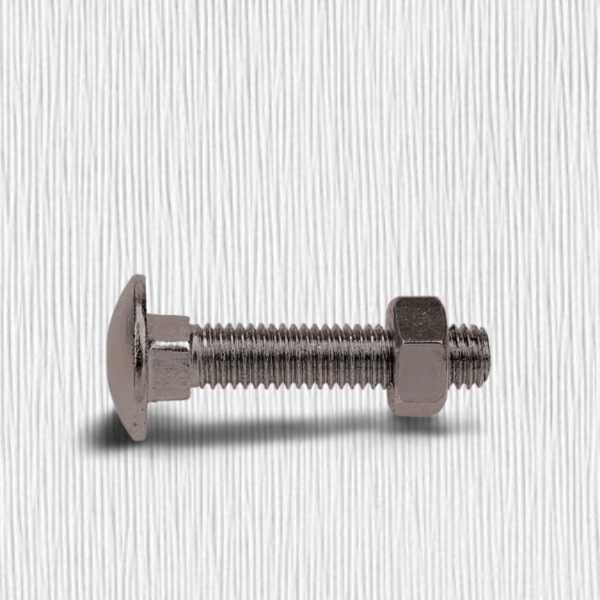

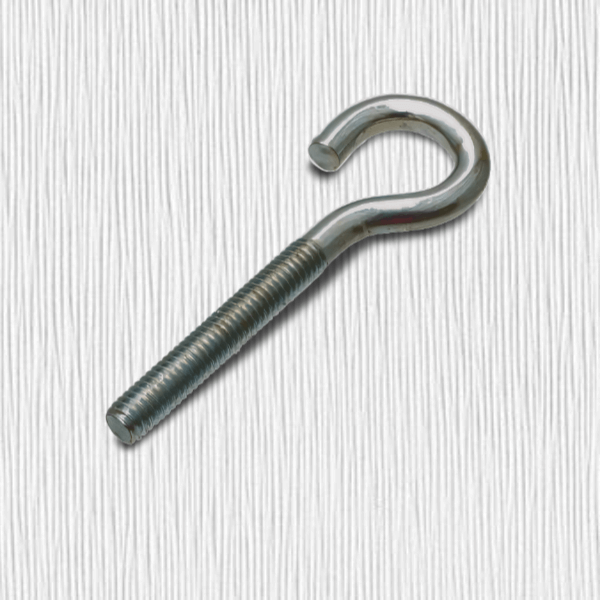

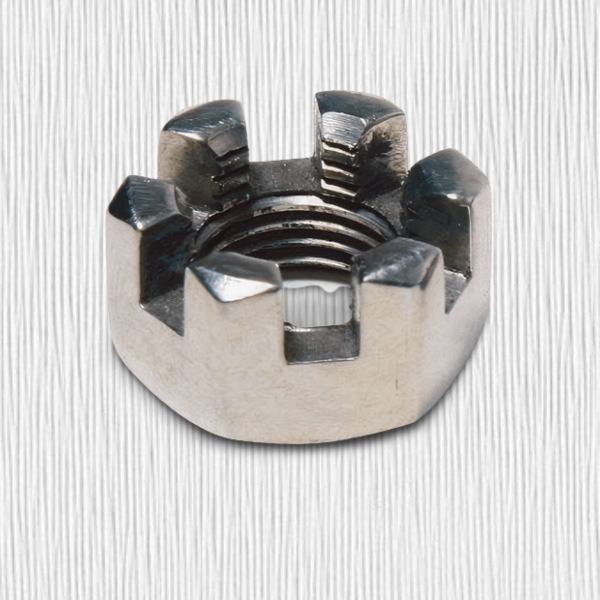

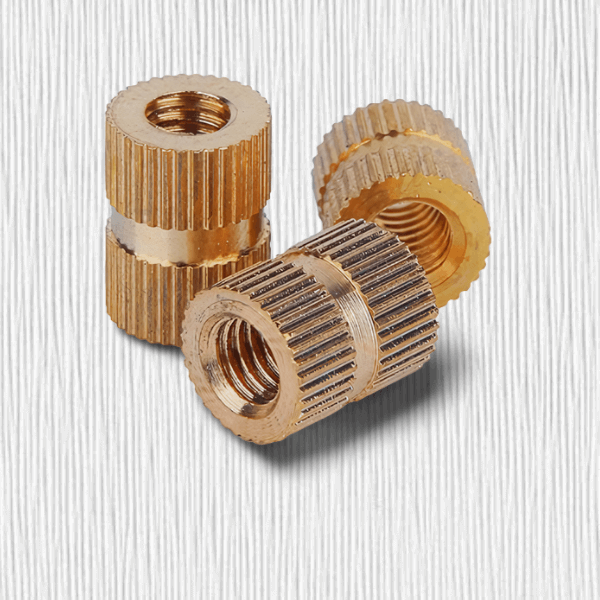

ASME SB574 Hastelloy C276 Hex Nut, ASTM 574 Hastelloy C276 Nut, ASME SB574 Hastelloy C276 Bolt, UNS N10276 Threaded Rod, Werkstoff Nr 2.4819 Threaded Rod, ASME SB574 Hastelloy C276 Hex Nut, ASTM 574 Hastelloy C276 Fasteners, ASTM 574 Hastelloy C276 Nut, UNS N10276 Stud Bolt

Hastelloy C276 is a super-strong nickel alloy. It resists corrosion extremely well. Fasteners made from it are vital in industries. This alloy contains nickel, chromium, and molybdenum. Fasteners like bolts and screws hold machinery together. They’re crucial components in manufacturing plants. Oil rigs need secure fasteners to operate safely. Aerospace and automotive plants rely on them too. The fasteners experience extreme forces and environments. They face high heat and pressure. Chemicals and abrasive particles could degrade them. Factories have machinery with spinning parts secured by fasteners. If they loosen, the results could injure workers. That’s why trusted fasteners are vital. Manufacturing plants handle hazardous materials like chemicals or molten metal.

Fasteners are exposed to those extreme substances daily. Only the strongest, most corrosion-proof fasteners suffice. Across construction, factories, mills, and plants, fasteners hold everything together. Their reliability enables safe, productive operations. That’s why premium fasteners are so highly valued. Hastelloy fasteners excel due to their superior corrosion resistance. They withstand exposure to acids, salt, chlorides, and more. This prevents pitting or crevice corrosion. At high temperatures over 1000°F, Hastelloy remains stable. It retains full mechanical strength in those intense conditions. This nickel-chromium alloy is exceptionally strong yet ductile too. Hastelloy fasteners provide long-lasting, ultra-reliable performance.

These fasteners are also hugely versatile. Their corrosion resistance suits many harsh industrial settings. They’re compatible with securing different material pairings too. That makes UNS N10276 Stud Bolt ideal for demanding applications.

Specification Of Hastelloy C276 Fasteners

| Specification | ASTM B574 / ASME SB574 |

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

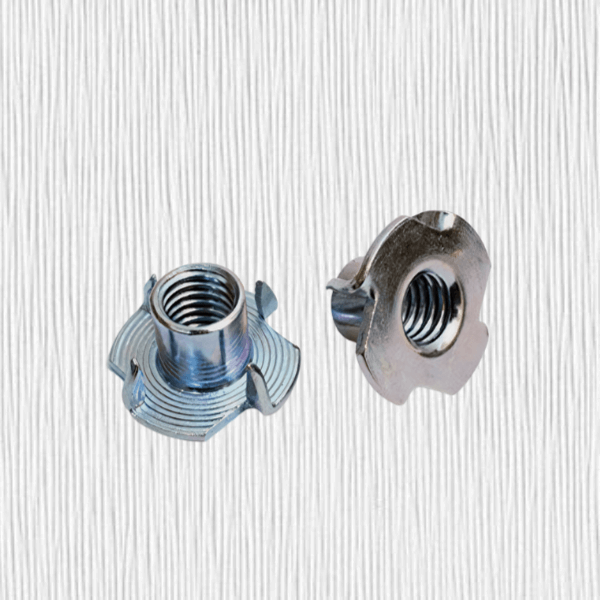

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Hastelloy C276 Fasteners

-

ASTM 574 Hastelloy C276 Washer US $44 - $50 / Kg

-

Werkstoff Nr 2.4819 Bolt US $46 - $47 / Kg

-

UNS N10276 Screw US $44 - $46 / Kg

-

ASME SB574 Hastelloy C276 Nut US $47 - $50 / Kg

-

ASTM 574 Hastelloy C276 Fasteners US $45 - $49 / Kg

Equivalent Grades Of Hastelloy C276 Fasteners

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C276 | N10276 | 2.4819 | - | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

Chemical Composition Of Hastelloy C276 Fasteners

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C276 | Balance | 0.01 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

Mechanical Properties Of Hastelloy C276 Fasteners

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Different Types Of Hastelloy C276 Fasteners

Our Manufacturing Process Of Hastelloy C276 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Fasteners

Our Material

Contact Us

Supplying World Wide