Hastelloy X Fasteners

Home » Hastelloy X Fasteners

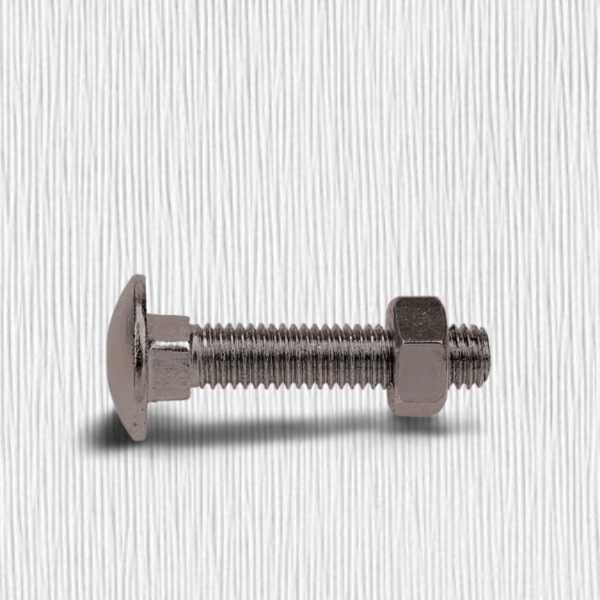

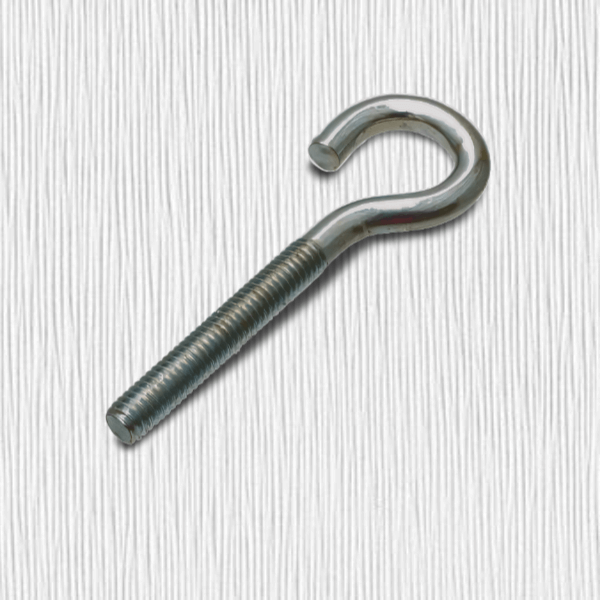

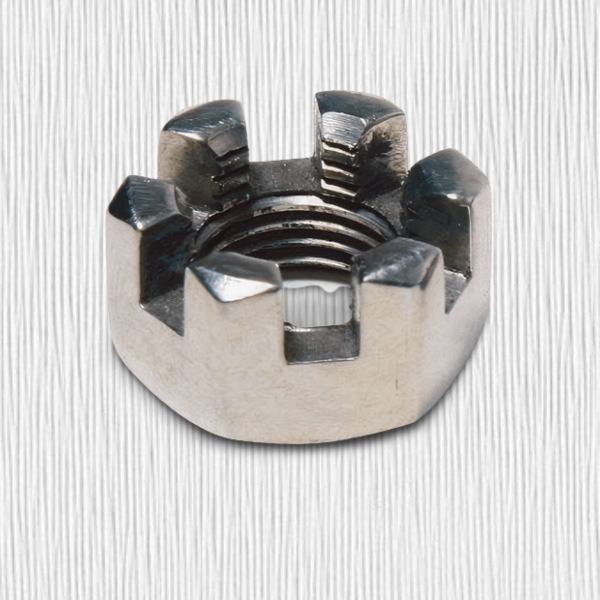

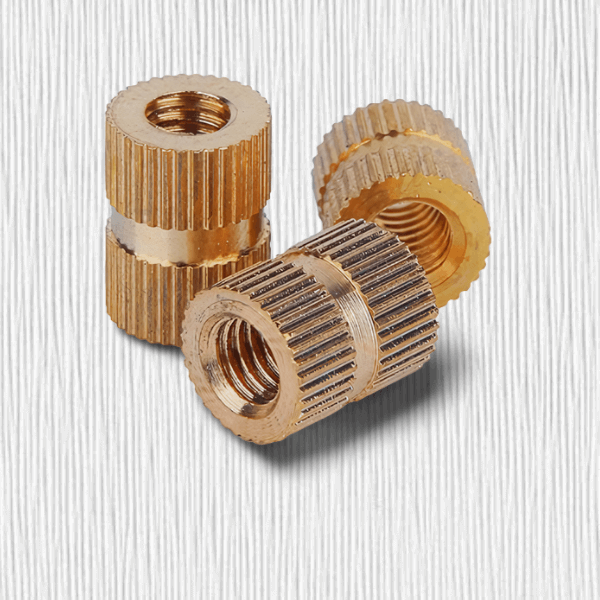

ASTM B572 Hastelloy X Fasteners, ASME SB572 Hastelloy X Bolt, ASTM B572 Hastelloy X Nut, UNS N06002 Stud Bolt, ASME SB572 Hastelloy X Threaded Rod, DIN 2.4665 Hex Nut, UNS N06002 Stud Bolt, ASTM B572 Hastelloy X Nut, ASME SB572 Hastelloy X Fasteners, DIN 2.4665 Bolt.

Hastelloy X is a nickel-based superalloy. Hastelloy X contains nickel, iron, chromium and other metals and this gives it distinct characteristics. It is resilient to extremely high temperatures and does not corrode easily in tough environments. What distinguishes UNS N06002 Stud Bolt is the fact that it is resistant to corrosion, and abrasion, and can outperform other materials when the latter fail. Industries like aerospace, chemical processing, and energy generation heavily depend on it. Fasteners must withstand operating conditions reliably like extreme temperatures, corrosive chemicals, vibrations and more. The wrong fastener can lead to failures. Their superior properties prevent premature failures and protect personnel, equipment and operations.

High-temperature resistance is key. ASME SB572 Hastelloy X Bolt perform at temperatures over 1000°C so they don’t become brittle or lose strength. Corrosion resistance is another advantage. The alloy resists oxidation and attacks by acids, alkalies and more. Unmatched strength makes Hastelloy X ultra-durable as it doesn’t deform or break down easily under heavy stresses. Environment compatibility is valuable so these fasteners suit underwater, high-pressure and other extreme service conditions.

Aerospace uses are widespread, from jet engines to launch vehicles, these fasteners excel. Chemical plants handling corrosive substances need them and their high integrity prevents leaks and accidents. Nuclear reactors also rely on Hastelloy X’s radiation resistance. Race cars and other high-performance vehicles use these premium fasteners.

DIN 2.4665 Bolt offer unbeatable performance advantages. Their high-temperature strength and corrosion resistance are vital for critical applications. These premium fasteners prevent failures and downtime. They optimize safety, reliability and productivity across industries.

Specification Of Hastelloy X Fasteners

| Specification | ASTM B572 / ASME SB572 |

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

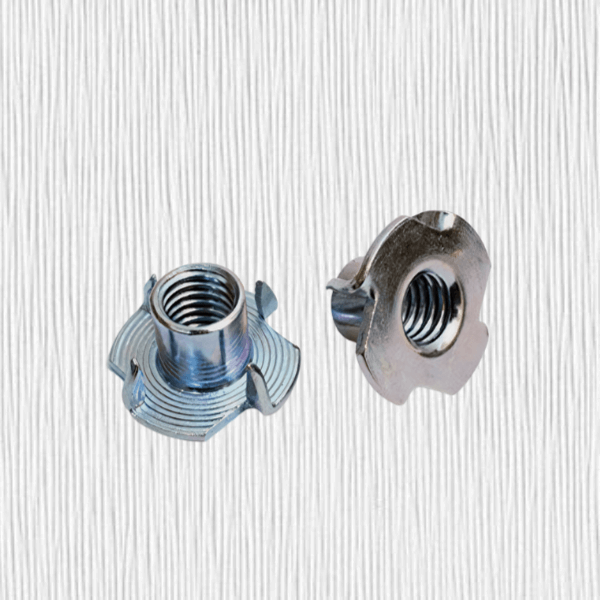

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Hastelloy X Fasteners

-

ASTM B572 Hastelloy X Washer US $44 - $50 / Kg

-

ASME SB572 Hastelloy X Bolt US $46 - $47 / Kg

-

UNS N06002 Screw US $44 - $46 / Kg

-

DIN 2.4665 Nut US $47 - $50 / Kg

-

ASTM B572 Hastelloy X Fasteners US $45 - $49 / Kg

Equivalent Grades Of Hastelloy X Fasteners

| STANDARD | UNS | WNR. |

| Hastelloy X | N06002 | 2.4665 |

Chemical Composition Of Hastelloy X Fasteners

| Grade | C | Mn | Si | Cu | Co | Ni | Cr | Fe | Mo | Ti |

| Hastelloy X | 0.05 – 0.15 | 1.0 max | 1.0 max | 0.50 max | 0.5 – 2.5 | Remainder | 20.5-23.0 | 17.0-20.0 | 8.0-10.0 | 0.15 max |

Mechanical Properties Of Hastelloy X Fasteners

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 9.2 g/cm3 | 1370 °C (2500 °F) | Psi – 51,000, MPa – 350 | Psi -1,10,000, MPa -760 | 40 % |

Different Types Of Hastelloy X Fasteners

Our Manufacturing Process Of Hastelloy X Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Hastelloy Fasteners

Our Material

Contact Us

Supplying World Wide