Inconel 617 Forged Fitting

Home » Inconel 617 Forged Fitting

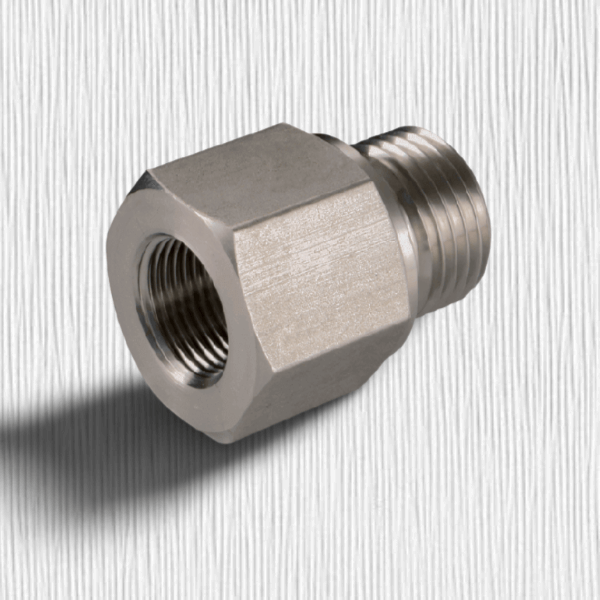

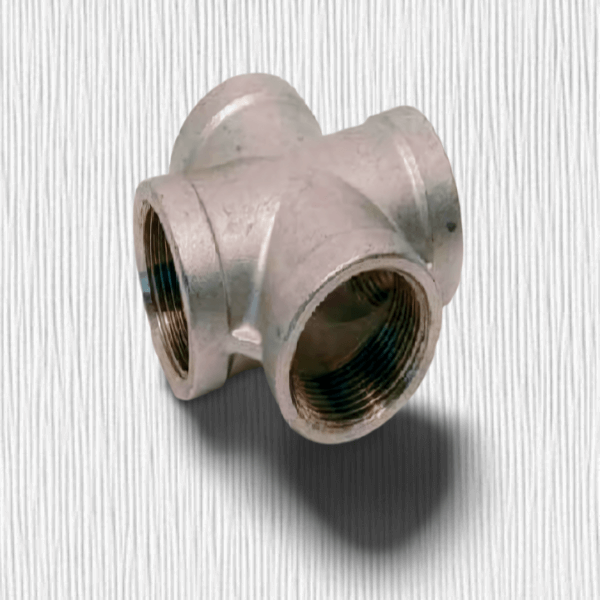

UNS N06617 Forged Adapter Fitting, ASTM B366 Inconel 617 Forged Cap, ASME SB366 Inconel 617 Forged Threaded Reducing Tee, ASTM B366 Inconel 617 Forged Threaded Plug, ASTM B366 Inconel 617 Forged Threaded Pipe Nipples, DIN 2.4663 Forged Threaded Lateral Tee, UNS N06617 Forged Half Coupling, ASME SB366 Inconel 617 Forged Cross, DIN 2.4663 Forged Sockolet Fitting, ASTM B366 Inconel 617 Forged Tee.

Inconel 617 a nickel chromium cobalt molybdenum alloy is well known for its properties at temperatures and resistance, to corrosion. When crafted into forged fittings Inconel 617 plays a role in industries that demand performance in extreme temperatures. These fittings ensure reliability, longevity and strength in conditions.

UNS N06617 Forged fittings made from Inconel 617 display resilience to temperatures retaining their mechanical characteristics even in environments surpassing 2000°F (1093°C). This ability to withstand heat makes them perfect for applications where thermal stability is vital.

Moreover the alloys resistance to corrosion extends to environments such as oxidizing and reducing conditions, acidic solutions and seawater. Inconel 617 forged fittings promise enduring reliability in settings reducing the risks of deterioration and breakdown.

By undergoing the forging process Inconel 617 fittings gain increased strength and durability that equip them to endure pressure and high stress operations. Their sturdy build lessens the chances of failures ensuring performance under demanding circumstances.

Inconel 617s remarkable resistance to oxidation and creep sets it as an option, for components exposed to prolonged periods of high temperatures. The alloys capacity to preserve its integrity under conditions further solidifies its suitability for critical applications.

We provide a few essential test certification copies to the buyers such as radiography test report 100 %, Raw Material Certificate, Mill Test Certifications according to EN 10204/3.1b, customers report, and third-party test reports.

ASTM B366 Inconel 617 Forged Threaded Fitting are carefully crafted using manufacturing methods to guarantee accuracy, dependability and excellence. By undergoing the forging process the materials mechanical characteristics are improved, leading to fittings that satisfy performance criteria. Rigorous testing and compliance, with industry norms ensure the reliability and functionality of Inconel 617 forged fittings.

Specification Of Inconel 617 Forged Fitting

| Specifications | ASTM B366 / ASME SB366 |

| Standard | ASME B16.11, MSS-SP-79, MSS-SP-83, MSS-SP-95, MSS-SP-97, BS3799 |

| Dimensions | ASME 16.11, MSS SP-79,83,95,97,BS 3799 |

| Size | 1/2"NB TO 4"NB IN |

| Class / Pressure | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | SOCKET WELD (S/W) & SCREWED (SCRD), Threaded – NPT, BSP, BSPT |

Price List Of Inconel 617 Forged Fitting

-

ASTM B366 Inconel 617 Forged Cap US $44 - $50 / Kg

-

ASME SB366 Inconel 617 Forged Cross US $46 - $47 / Kg

-

UNS N06617 Forged Adapter Fitting US $44 - $46 / Kg

-

DIN 2.4663 Forged Full Coupling US $47 - $50 / Kg

-

ASTM B366 Inconel 617 Forged Tee US $45 - $49 / Kg

Equivalent Grades Of Inconel 617 Forged Fitting

| STANDARD | UNS | WNR. |

| Alloy 617 | N06617 | 2.4663 |

Chemical Composition Of Inconel 617 Forged Fitting

| C | Mn | S | Si | Cr | Mo | Ni | Cu | Ti | Al | B | Co | Fe |

| 0.05-0.15 | 1.0 Max | 0.015 Max | 1.0 Max | 20.0-24.0 | 8.0-10.0 | 44.5 Min | 0.5 Max | 0.6 Max | 0.8-1.5 | 0.006 Max | 10.0-15.0 | 3.0 Max |

Mechanical Properties Of Inconel 617 Forged Fitting

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

Different Types Of Inconel 617 Forged Fitting

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Forged Fitting

Our Material

Contact Us

Supplying World Wide