Alloy 28 Fasteners

Home » Alloy 28 Fasteners

DIN 1.4563 Bolt, UNS N08028 Nut, ASME Alloy 28 Hex Nut, UNS N08028 Fasteners, DIN 1.4563 Fasteners, ASTM Alloy 28 Alloy 29 Alloy 28 Stud Bolt, ASME Alloy 28 Hex Nut, UNS N08028 Nut, DIN 1.4563 Threaded Rod, ASME Alloy 28 Bolt, ASTM Alloy 28 Alloy 29 Alloy 28 Threaded Rod.

Alloy 28 is a remarkable nickel-iron-chromium alloy with superior properties. Fasteners are vital components across many industries. Alloy 28 bolts is an age-strengthened nickel-iron-chromium-molybdenum alloy. Compared to regular stainless, Alloy 28 offers far greater protection.

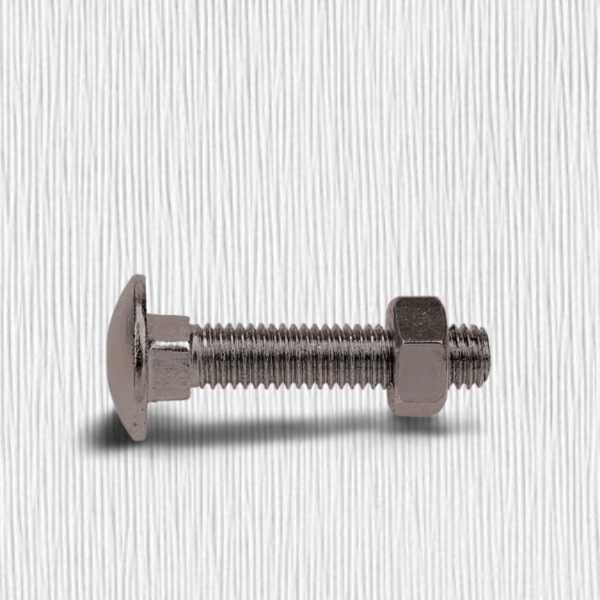

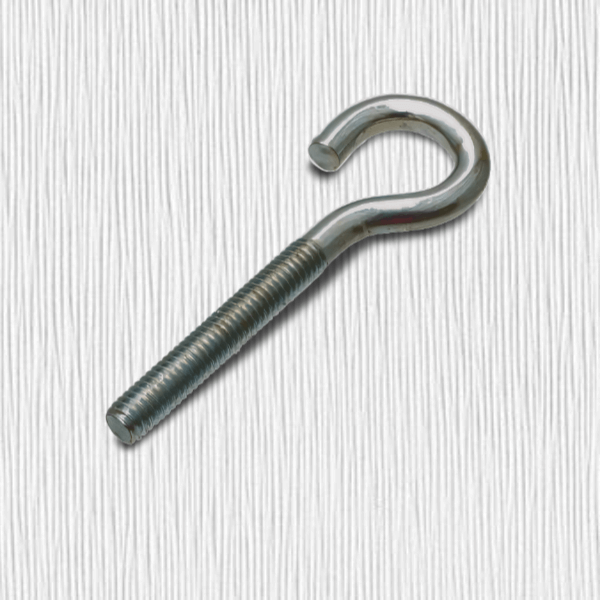

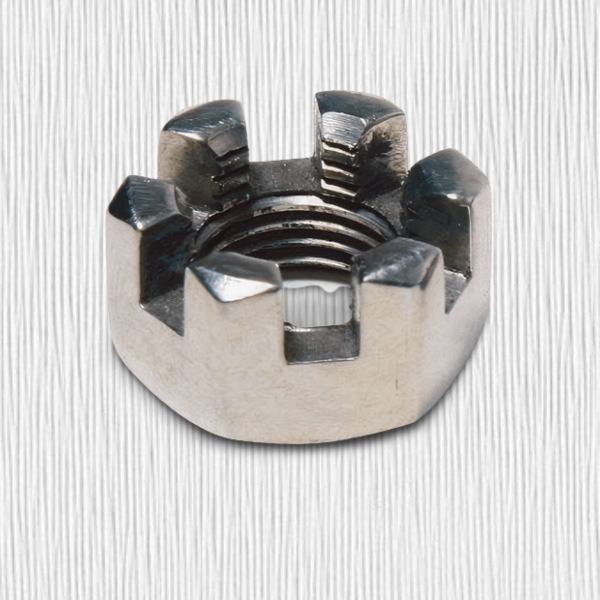

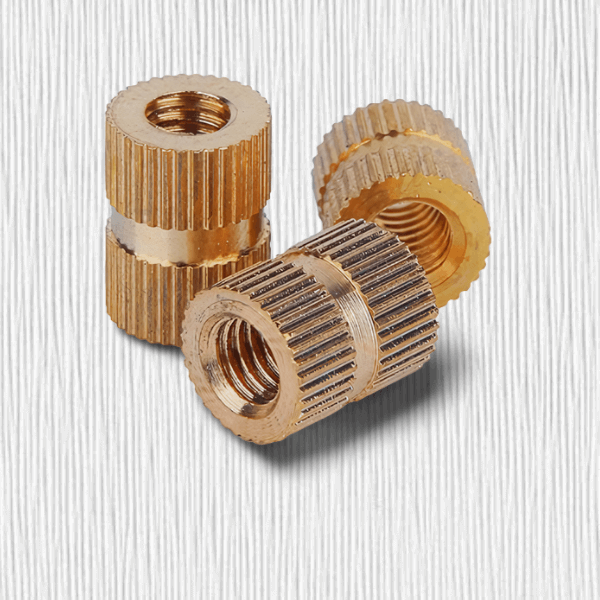

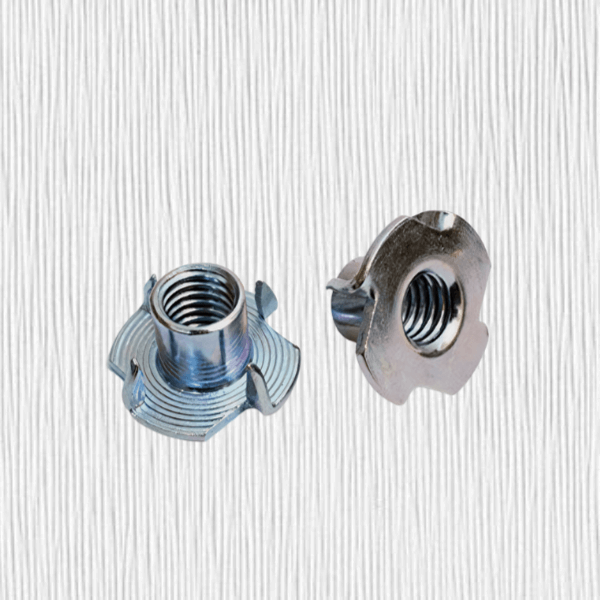

UNS N08028 Fasteners come in various forms – nuts, bolt threads, bolts providing removable fastening solutions, screws that drive into materials semi-permanently, washers distributing loads evenly to prevent galling, studs acting as permanent threaded stands, and custom shapes like U-bolts, anchors or turnbuckles tailored for specialized needs. This diverse range ensures reliable, long-lasting fastenings.

The exceptional corrosion resistance makes Alloy 28 indispensable in chemical processing plants handling reactive substances. Its ability to withstand harsh offshore environments sees extensive use in oil and gas operations. Shipbuilding and offshore rigs use its anti-seawater properties. Pharmaceutical manufacturing areas require hygienic, chemically inert material construction that WNR 1.4563 Fasteners provides. Nuclear power facilities need radiation-resistant components like these fasteners. Other specialised hostile-service applications include pollution control equipment, mining operations and desalination plants.

Phenomenal corrosion resistance against chemicals, seawater, acids and more is a key benefit. The longevity and durability allow decades of service in punishing conditions where other materials fail quickly. An exceptionally high strength-to-weight ratio enables lighter-weight yet heavy-duty component designs. Resistance to extreme temperatures up to 2000°F without integrity loss is crucial. Unlike coatings that can chip or wear, Alloy 28’s protection is inherent throughout the material.

Alloy 28 fasteners deliver unparalleled corrosion resistance combined with superior high-temperature strength. These standout properties make them indispensable for components in chemical processing, marine, nuclear, and other hostile operating environments where maximum durability and reliability are paramount.

Renine Metalloys LLP is a trustworthy Alloy 28 supplier & Manufacturer of all Alloy products. Contact us for more details on the Alloy 28 fasteners price.

Specification Of Alloy 28 Fasteners

| Dimensional specification | ASTM, ASME and API |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Length | 3 mm to 200 mm |

| Form | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Alloy 28 Fasteners

-

UNS N08028 Washer US $20 - $25 / Kg

-

DIN 1.4563 Bolt US $23 - $24 / Kg

-

ASTM Alloy 28 Screw US $22 - $23 / Kg

-

ASME Alloy 28 Nut US $24 - $25 / Kg

-

UNS N08028 Fasteners US $21 - $22 / Kg

Equivalent Grades Of Alloy 28 Fasteners

| STANDARD | UNS | WERKSTOFF NR. |

| Alloy 28 | N08028 | 1.4563 |

Chemical Composition Of Alloy 28 Fasteners

| Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

| 30-32 | 22 min | 26-28 | 3-4 | 0.60-1.40 | - | 0.02 max | 2 max | 0.03 max | 0.70 max | - |

Different Types Of Alloy 28 Fasteners

Our Manufacturing Process Of Alloy 28 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Alloy Fasteners

Our Material

Contact Us

Supplying World Wide