Duplex 31803 Plate

Home » Duplex 31803 Plate

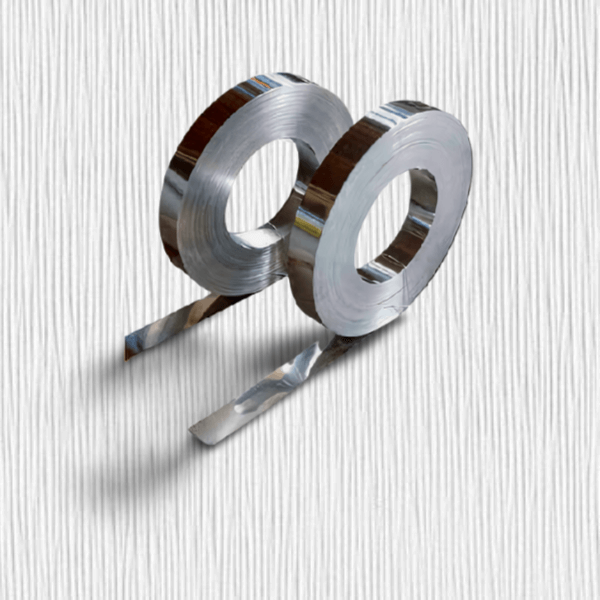

UNS S31803 Circle, UNS S31803 Ring, ASTM A 240 Duplex 31803 2B Finish, ASME SA 240 Duplex 31803 Plate, DIN 1.4462 Hot Rolled Sheet, ASTM A 240 Duplex 31803 Perforated Sheets, UNS S31803 Foil Sheet, ASME SA 240 Duplex 31803 Flats.

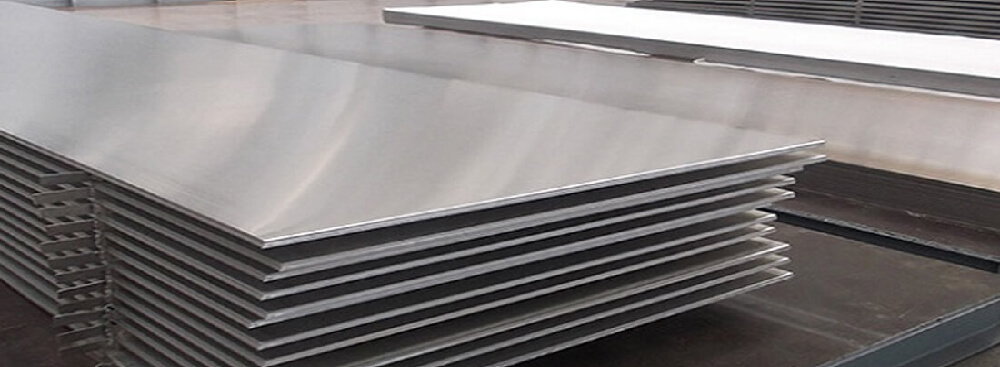

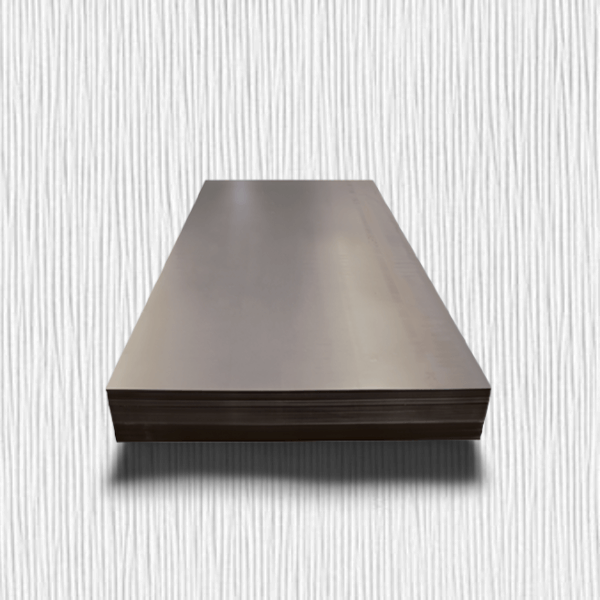

The Duplex 31803 Plate is a versatile and durable metal plate made from Duplex stainless steel. When rolled into plate form, 31803 achieves high strength for its weight, with nominal yield strength around 60,000 psi and tensile strength reaching 89,000 psi. At three-eighths of an inch thick, the plate retains good weldability for fabrication projects. Its density falls around 7.8 grams per centimetre cubed.

Despite higher strength than austenitic grades, the ASTM A 240 Duplex 31803 Perforated Sheets retains 30% to 60% elongation with high energy absorption during impact. This combination of strength and ductility facilitates use in pressure vessels and storage tanks.

The plate exhibits excellent resistance to pitting and crevice corrosion in harsh environments with chlorides or other contaminants. When heated between 1,500°F and 1,900°F, the Duplex plate forms an adherent, self-healing chromium oxide layer only a few nanometers thick. This chromium enrichment phenomenon further enhances corrosion performance while also providing good resistance to oxidation and scale buildup. So the material retains its surface qualities in high-temperature applications like heat exchangers and refinery process piping.

The plate metal is well suited to welding and other forms of material joining using standard duplex practices. Precautions include controlling heat input to avoid precipitation of intermetallic compounds.

Post-weld treatments such as pickling should be applied to remove oxides and fully restore corrosion resistance. Machining the plate for fabrication also requires correct techniques and tooling but can be performed with good productivity at optimal conditions.

Due to its high mechanical strength, weldability, appreciable ductility, outstanding corrosion performance, and overall ease of fabrication, the UNS S31803 Foil Sheet offers versatility across many process industries.

It provides durable service for pipes, tanks, pressure vessels, offshore platforms, pumps and valves, and any components exposed to oxidizing acids, chlorine bearing environments, or high temperatures. With proper joining techniques and handling precautions applied, the properties of 31803 can be fully utilized to improve critical infrastructure integrity and lifecycle costs.

Renine Metalloys LLP is a trustworthy Duplex 31803 plate supplier & Manufacturer of all Duplex products. Contact us for more details on the Duplex 31803 price per kg

Specification Of Duplex 31803 Plate

| Specifications | ASTM A240 / ASME SA240 |

| Dimensional specification | JIS, AISI, ASTM, GB, DIN, EN, etc |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Thickness | 4mm-100mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

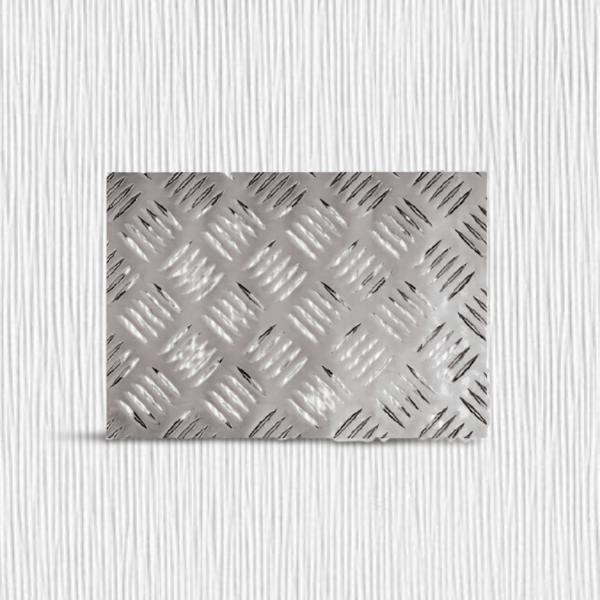

| Surface Finish | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc. |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

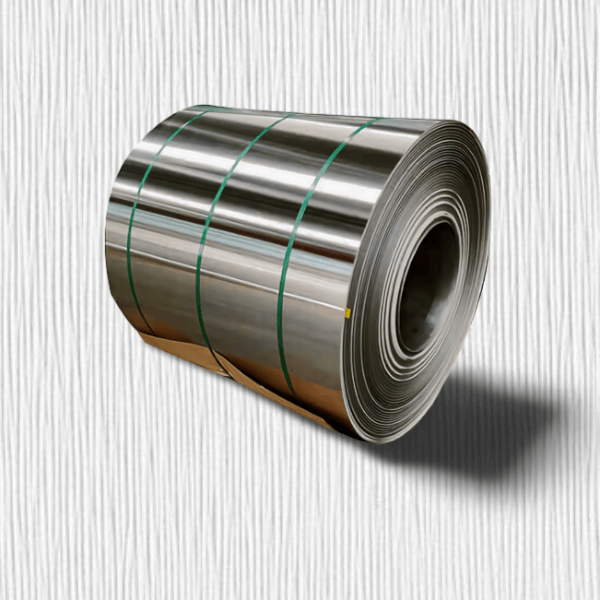

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

| Surface Finish | No.1, No.4, No.8 Mirror Finish, 2B |

Price List Of Duplex 31803 Plate

-

ASTM A 240 Duplex 31803 2B Finish US $5 - $6 / Kg

-

ASME SA 240 Duplex 31803 Coil US $5 - $6 / Kg

-

UNS S31803 Circle US $5 - $6 / Kg

-

DIN 1.4462 Clad Plate US $5 - $6 / Kg

-

ASTM A 240 Duplex 31803 CR Sheet US $5 - $6 / Kg

Equivalent Grades Of Duplex 31803 Plate

| STANDARD | UNS | WERKSTOFF NR. |

| Duplex 2205 | S31803 | 1.4462 |

Chemical Composition Of Duplex 31803 Plate

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

Mechanical Properties Of Duplex 31803 Plate

| Density (g/cm 3) | Melting Point | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000 , MPa – 800 | Psi – 80000 , MPa – 550 | 15 % |

Different Types Of Duplex 31803 Plate

Our Manufacturing Process Of Duplex 31803 Plate

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Duplex Plate

Our Material

Contact Us

Supplying World Wide