Incoloy 825 Flanges

Home » Incoloy 825 Flanges

JIS NCF 825 Wnrf Flange, DIN 2.4858 Weld-Neck Flange, UNS N08825 Forging Facing Flange, ASTM B564 Incoloy 825 Socket-Weld Flange, JIS NCF 825 Nuts-Bolts Flange, ASTM B564 Incoloy 825 Weld-Neck Flange-A-B, DIN 2.4858 Lap-Joint Flange, DIN 2.4858 Reducing Flange, UNS N08825 Swrf Flange.

Renine Metalloys LLP, a distinguished manufacturer and supplier, is lauded for its comprehensive array of UNS N08825 Forging Facing Flange. These flanges conform to varying standards and specifications, adhering to the highest durability and performance excellence level. We affordably provide these high-calibre flanges to our global clientele, tailoring them to suit diverse industrial requirements. Slip-on, weld neck, blind flange, ring joint flanges, and more are available in numerous grades, sizes, standards, and dimensions.

Incoloy 825 is a renowned austenitic alloy crafted from copper, nickel, chromium, iron, and molybdenum. It excels in corrosion resistance, even in reducing and aggressive environments. The alloy contains copper, nickel, and molybdenum, which improves resilience in reducing atmospheres.

At the same time, its chromium content imparts oxidation resistance when exposed to a nitric acid solution, oxidizing salts and nitrates. We harness the prime quality of this alloy in our manufacturing process to create flanges of exceptional quality. The resultant ASTM B564 Incoloy 825 Blind Flange excel in stress corrosion resistance, particularly in chloride solutions, exhibiting a sturdy defence against pitting, oxidation, abrasion, and crevice corrosion.

Renine Metalloys LLP is committed to meeting our clients’ exact demands by delivering dimensionally precise, defect-free Incoloy 825 Flanges. We mandate rigorous testing of each flange before delivery to ensure client satisfaction and production accuracy. Supervised by our quality control team, the Incoloy 825 Flanges undertake numerous quality assessments. Our industry experts maintain a keen eye over each manufacturing and testing process, certifying optimal product quality.

We sustain considerable stock levels of Incoloy 825 Flanges, ever ready to satisfy the immediate demands of our worldwide clientele. Our dedication extends to delivering Incoloy 825 Flanges safely and promptly, ensuring buyer satisfaction. Aided by our proficient packaging team, these flanges are packed using suitable materials to safeguard them from potential damage and rust during transit. Leveraging efficient shipping options, we consistently ensure minimal delivery times.

Specification Of Incoloy 825 Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Incoloy 825 Flanges

-

JIS NCF 825 Orifice Flange US $20 - $25 / Kg

-

DIN 2.4858 Reducing Flange US $23 - $24 / Kg

-

ASTM B564 Incoloy 825 Ring-Type-Joint Flange US $22 - $23 / Kg

-

UNS N08825 RTJ Flange US $24 - $25 / Kg

-

JIS NCF 825 Screwed Flange US $21 - $22 / Kg

Equivalent Grades Of Incoloy 825 Flanges

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 825 | N08825 | 2.4858 | NC22DNB4M | NiCr22Mo9Nb | NCF 825 | NA 21 | ЭП703 | ЭИ602 |

Chemical Composition Of Incoloy 825 Flanges

| Grade | C | Mn | Si | S | Al | Ti | Fe | Ni | Cr |

| Incoloy 825 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 0.40 max | 0.40 max | 5.0 max | 58.0 min | 20.0 - 23.0 |

Mechanical Properties Of Incoloy 825 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Different Types Of Incoloy 825 Flanges

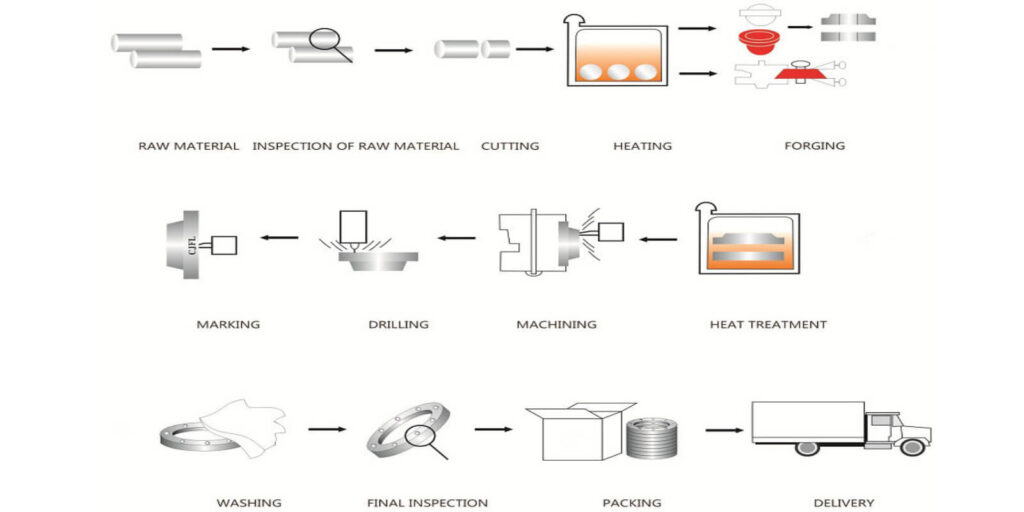

Our Manufacturing Process Of Incoloy 825 Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Flanges

Our Material

Contact Us

Supplying World Wide