Inconel 725 Fasteners

Home » Inconel 725 Fasteners

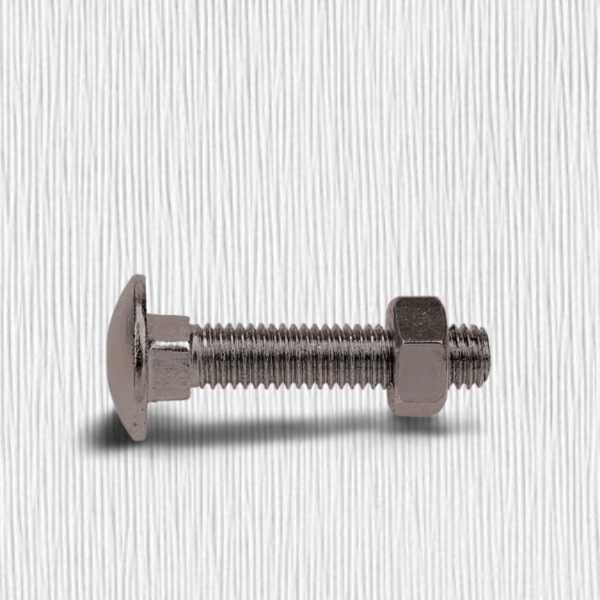

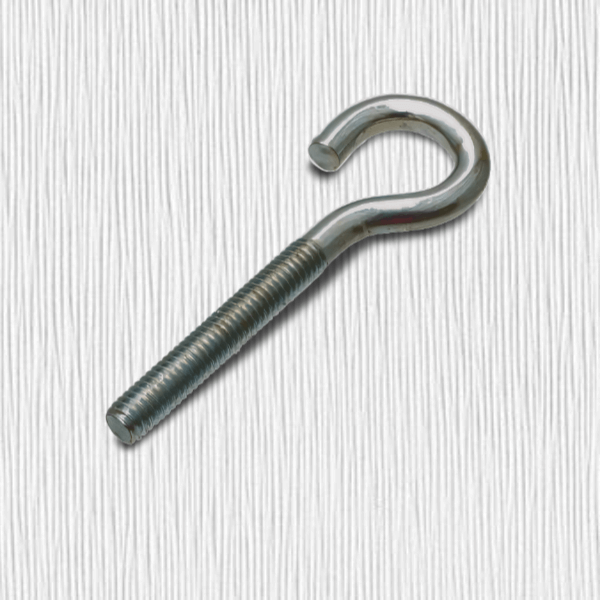

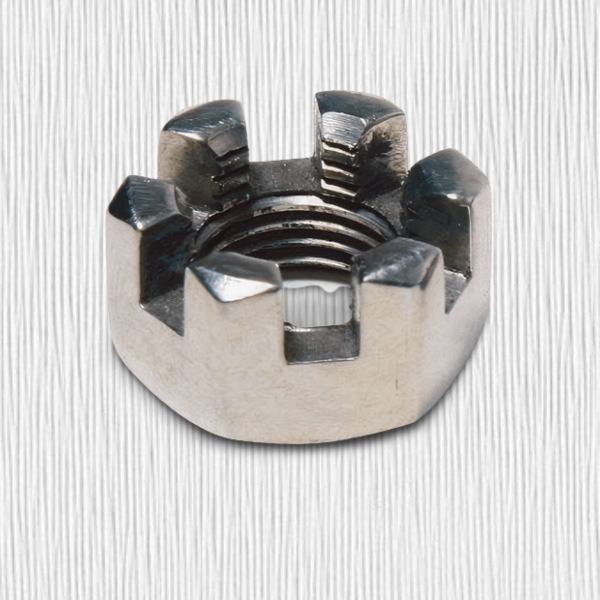

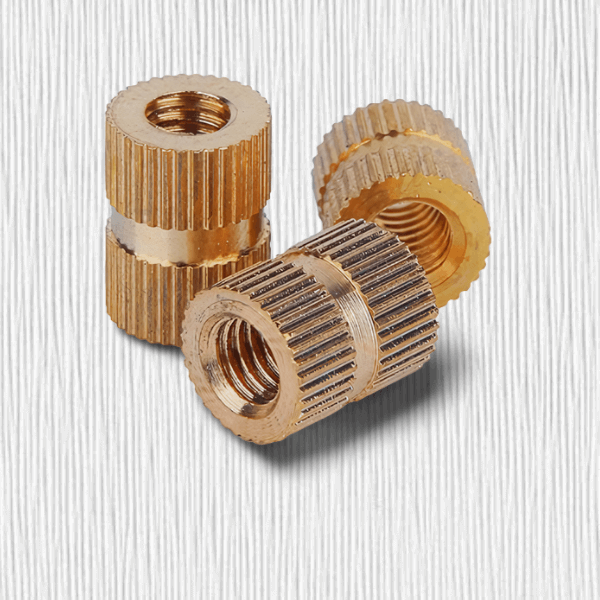

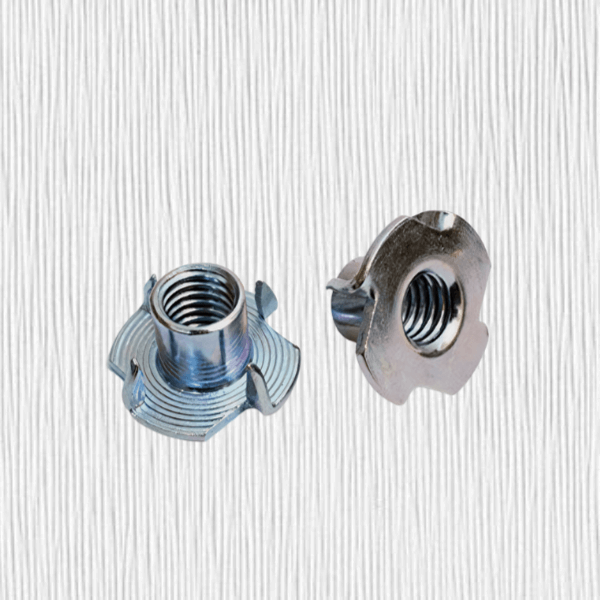

ASME SB166 Inconel 725 Hex Nut, JIS NCF 725 Bolt, UNS N07725 Stud Bolt, JIS NCF 725 Threaded Rod, ASME SB166 Inconel 725 Hex Nut, JIS NCF 725 Fasteners, UNS N07725 Stud Bolt, ASTM B166 Inconel 725 Nut, ASTM B166 Inconel 725 Fasteners, ASTM B166 Inconel 725 Nut, UNS N07725 Threaded Rod.

Inconel 725 is a super-alloy often used for fasteners. This nickel-based alloy is incredibly strong and corrosion-resistant. Its main elements are nickel, chromium, and molybdenum. There are also elements like niobium and titanium that enhance performance.

ASTM B166 Inconel 725 Fasteners can withstand extreme temperatures well. From scorching 1800°F to frigid -320°F, they endure and high strength is maintained across this broad range. Such robust fasteners are ideal for high-stress applications like aerospace components, turbochargers, and chemical plants – they’re everywhere crucial.

Reliability in severely corrosive or high-heat conditions matters which is provided by these fasteners. These alloy fasteners are also highly resistant to creep and creep causes metals to deform slowly under stress. So JIS NCF 725 Bolt hardware retains integrity over time.

Manufacturing processes like forging produce superior fastener strength. Each fastener contains a uniform composition and microstructure throughout. While manufacturing, the quality assurance protocols certify consistently high standards met.

Though expensive compared to ordinary steel fasteners, Inconel’s worth it. Superior performance justifies costs for critical, demanding uses. So for extreme environments, caustic chemicals, and high temperatures – Nickel alloy fasteners answer the demanding call reliably. UNS N07725 Stud Bolt hardware exhibits unparalleled durability under duress.

Beyond just temperature and corrosion resistance, important traits:

- Inconel 725 has excellent fatigue strength and toughness.

- Under high cyclical stresses, these fasteners won’t crack.

- Their overall durability is truly impressive and long-lasting.

When dismantling equipment, reusability proves advantageous too. As long as no degradation occurs, Inconel 725 fasteners perform very well. They can be removed, reconditioned, and reinstalled repeatedly and this reusability helps maximize the value of the investment.

Renine Metalloys LLP is a trustworthy Inconel 725 supplier & Manufacturer of all Inconel products. Contact us for more details on the Inconel 725 fasteners price.

Specification Of Inconel 725 Fasteners

| Standard | ASTM B166, ASME SB166 |

| Dimensions | ANSI B18.2.2, DIN 934,ISO 4032, BS1768, BS 1769 |

| Length | 3 mm to 200 mm |

| Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Type | Bolts, Nuts, Sockets, Screws, Screw, Studs, Socket Screw, Hex Set Screw, Cap Screw, Machine Screw, Pan Head Screw, Allen Cap screw, Socket Head Cap Screw, Wing Screw, Spring Washers, Washers, Studs, Marine Anchors, Anchors, Hexagon Nut, Nut, Hex Coupling Nut, Hex Nut, Square Nut, Hex Domed Cap Nuts, Hex Head Bolts, Stud Bolts, Socket Hexagon Head Screw,U- Bolts, Anchor Bolt, Mushroom Head Square Neck Bolts, J Bolts, Wing Screw, T-Head Bolts, Foundation Bolts, Eye Bolt,Structural Bolts. |

Price List Of Inconel 725 Fasteners

-

ASTM B166 Inconel 725 Washer US $44 - $50 / Kg

-

JIS NCF 725 Bolt US $46 - $47 / Kg

-

UNS N07725 Screw US $44 - $46 / Kg

-

ASME SB166 Inconel 725 Nut US $47 - $50 / Kg

-

ASTM B166 Inconel 725 Fasteners US $45 - $49 / Kg

Equivalent Grades Of Inconel 725 Fasteners

| STANDARD | UNS | WNR. |

| Inconel 725 | N06725 | 2.4856 |

Chemical Composition Of Inconel 725 Fasteners

| Elements | Nickel, Ni | Chromium, Cr | Iron, Fe | Molybdenum, Mo | Niobium, Nb (Columbium, Cb) | Titanium, Ti | Aluminum, Al | Manganese, Mn | Silicon, Si | Carbon, C | Phosphorous, P | Sulfur, S |

| Content (%) | 55 – 59 | 19 – 22.5 | 9 | 7 – 9.50 | 2.75 – 4 | 1 – 1.70 | 0.35 | 0.35 | 0.2 | 0.03 | 0.015 | 0.01 |

Mechanical Properties Of Inconel 725 Fasteners

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.31 g/cm3 | 1271°C-1343 °C | 1137 MPa | 827 MPa | 20 % |

Different Types Of Inconel 725 Fasteners

Our Manufacturing Process Of Inconel 725 Fasteners

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Inconel Fasteners

Our Material

Contact Us

Supplying World Wide