Incoloy 800HT Flanges

Home » Incoloy 800HT Flanges

JIS NCF 800HT Screwed Flange, ASTM B564 Incoloy 800HT Square Flange, ASTM B564 Incoloy 800HT Ring-Type-Joint Flange, JIS NCF 800HT Orifice Flange, DIN 1.4959 Weld-Neck Flange, DIN 1.4959 Spectacle-Blind Flange, UNS N08811 RTJ Flange, DIN 1.4959 Slip-On Flange, UNS N08811 Spades-Rings-Spacer Flanges.

Renine Metalloys LLP, a renowned organization, excels in producing and providing various feature-rich Incoloy 800HT Flanges. We fabricate high-quality flanges embodying diverse specifications, standards, sizes, dimensions, and types. Our offerings cater to both standard and bespoke specifications in line with the varied requirements of our esteemed global customer base.

Incoloy 800HT is a composite alloy containing chromium, nickel, and iron. The formulation of Incoloy is further enriched by adding copper, molybdenum, nitrogen, and silicon. Two key members of the 800 alloy lineage – Incoloy 800H and 800HT – share a similar chemical constituency but possess slight variations in aluminium, carbon and titanium quantities.

The Incoloy 800HT alloy is exceptionally resistant to oxidation, corrosion, carburization, and sulfidation, properties which contribute to its wide usage in flange production. Our DIN 1.4959 Weld-Neck Flange are distinguished for excellent weldability, workability, and formability. The striking chemical formulation of these flanges endows them with enhanced tensile strength even under elevated temperatures and pressures. Moreover, these flanges exhibit increased stress rupture and creep-rupture capabilities under high temperatures. Using standard methods, Renine Metalloys ensures the flanges are flawlessly machinable and fabricable.

At Renine Metalloys LLP, we administer myriad destructive and non-destructive quality evaluations to ascertain the performance and longevity of JIS NCF 800HT Orifice Flange. Our adept quality auditors scrutinize various flange parameters under rigorous supervision at multiple manufacturing stages. Responsive to customer needs, we also accommodate third-party inspections of the Incoloy 800HT Flanges. These evaluations are executed at our well-appointed facility using automated tools.

Post-assessment, Incoloy 800HT Flanges that meet our exacting standards are carefully packaged using standard procedures. We are committed to delivering flanges punctually and in pristine condition, facilitated by our efficient transportation methods.

Specification Of Incoloy 800HT Flanges

| Specifications | ASTM B564 / ASME SB564 |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" (15 NB) to 48" (1200NB) |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Price List Of Incoloy 800HT Flanges

-

UNS N08811 Loose Flange US $20 - $25 / Kg

-

JIS NCF 800HT Orifice Flange US $23 - $24 / Kg

-

DIN 1.4959 Reducing Flange US $22 - $23 / Kg

-

ASTM B564 Incoloy 800HT Ring-Type-Joint Flange US $24 - $25 / Kg

-

UNS N08811 RTJ Flange US $21 - $22 / Kg

Equivalent Grades Of Incoloy 800HT Flanges

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Incoloy 800HT | N08811 | 1.4959 | - | X8NiCrAlTi32-21 | NCF 800HT | NA 15(HT) | ЭИ670 | XH32T |

Chemical Composition Of Incoloy 800HT Flanges

| Grade | Ni | Fe | Cr | Cu | Ti | Al | C | Mn | S | Si |

| Alloy 800HT | 30.0-35.0 | 39.5 min | 19.0-23.0 | .75 max | .25-.60 | .85-1.20 | .06-.10 max | 1.5 max | .015 max | 1.0 max |

Mechanical Properties Of Incoloy 800HT Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1350-1400 ℃ | Psi - 75,000 , MPa -520 | Psi - 30,000 , MPa - 205 | 30 - 35 % |

Different Types Of Incoloy 800HT Flanges

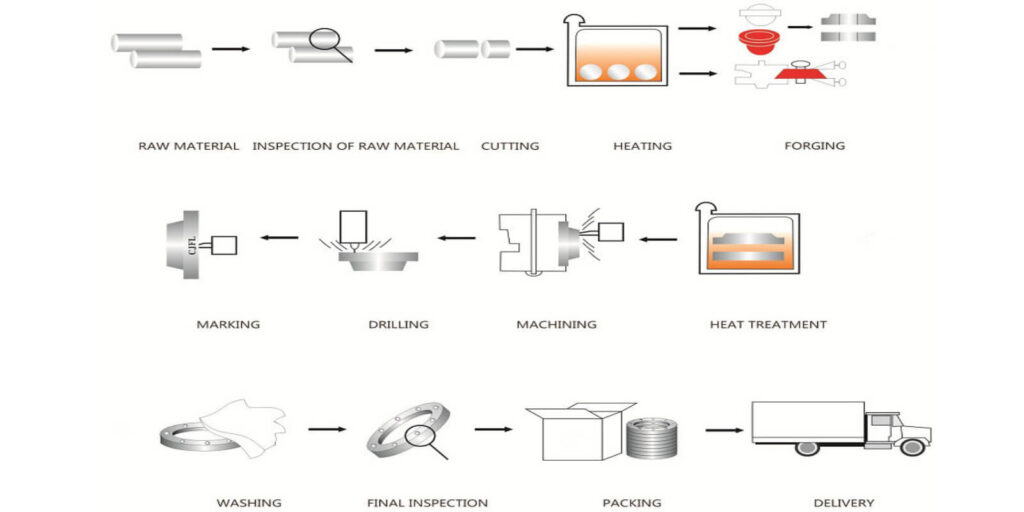

Our Manufacturing Process Of Incoloy 800HT Flanges

- Gears

- Aerospace & Aircraft

- Defense

- Oil & Petro Chemicals

- Energy & Power Generation

- Mining & Tunnel Boring

- Machinery Builders

- Metalworking Shops

- Shipbuilding

- Pulp & Paper

- Tidal (Wave) Energy

- Transportation

- Steel Service Centers

- Food Processing

- Valves And Pumps

- Engine & Turbine

- Ultrasonic Test (Ut)

- Magnetic Particle Inspection (Mpi)

- Liquid Penetrant Examination (Lpt)

- Positive Material Identification (Pmi)

- Boxes and Crates

- Carton boxes

- Wooden boxes

- Shrink-wrapped

People Also Search For

City We Deliver To

Country We Export To

Incoloy Flanges

Our Material

Contact Us

Supplying World Wide